Packaging plays a crucial role in various industries. Consumers, brands, and manufacturers rely on packaging to ensure safety, convenience, and a superior experience.

Maintaining the safety of food products is of the utmost importance in the food and beverage industry. The use of protective materials and processes is vital in keeping the food fresh inside and preventing external contaminants from entering.

Industries such as consumer packaged goods, restaurants, retail, E-commerce, and manufacturing consider various factors when selecting packaging materials, such as heat sealability, strength, printability, sustainability, and barrier properties like water, oil, and gas.

Data has become a crucial element in decision-making processes today, including packaging decisions. By analyzing historical data, brands and manufacturers can develop better packaging and processes to improve product safety and satisfy consumers. Data can also help identify the root causes of issues and highlight opportunities for improvement. Packaging is a significant component of product safety, and access to reliable data about your packaging and raw materials can ensure high quality packaging is delivered to consumers by brands and manufacturers.

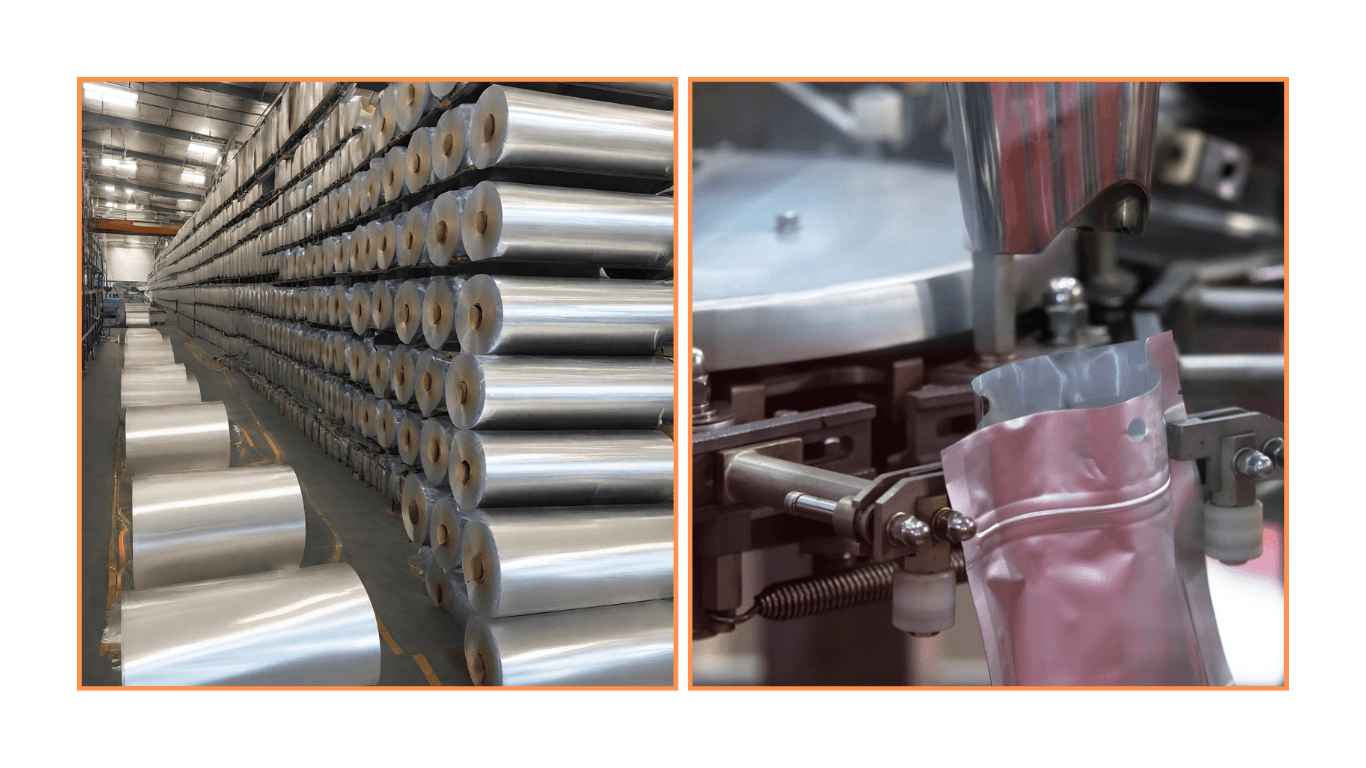

Flexible packaging is one such solution that offers a range of options to choose from depending on the nature of the product. For example, different types of food products such as dry goods, oily foods, and liquids, require different types of packaging materials and techniques. Flexible packaging provides a variety of choices that can cater to these varying requirements. It is not a one-size-fits-all solution, but rather a diverse set of options that can be customized to suit different products and their specific needs.

Flexible packaging can be customized to meet specific product requirements and offers excellent protection against moisture, oxygen, and UV light, which can significantly extend the shelf life of perishable products such as food and pharmaceuticals. From sleeves and pouches to bags and shrink film, we have your testing needs covered.

Corrugated packaging has earned a reputation as an excellent choice for shipping containers to preserve the safety and quality of many products. Food producers often choose corrugated packaging due to its durability and ability to withstand rough handling during transportation. Additionally, corrugated packaging is an eco-friendly option as it is recyclable.

With approximately 40% of all corrugated packaging being used in food manufacturing to keep products safe, consistent performance and meeting critical-to-quality parameters are extremely important.

Many companies across various industries prefer to use corrugated boxes for delivering their products because it provides excellent protection. Even though single wall boxes may appear thin, they can still shield their contents to a great extent. If you want to ensure that you are getting your money’s worth, you can test your corrugated boxes with Clear Packaging. By doing so, you will have access to relevant data, allowing you to make timely and confident decisions.

Did you know that paper and paperboards make up approximately one-third of the global packaging market?

These versatile materials are commonly used in the food packaging industry for a variety of purposes, such as protecting and containing food products, making them easier to store and consume, and providing important information to consumers regarding the product’s features and marketing aspects. Thanks to their versatility, affordability, and eco-friendliness, paper and paperboards have become a staple of the packaging industry and are widely used across the globe.

Polymers are widely used in the food and beverage industry for packaging purposes. This is because polymers possess excellent barrier properties that help to protect the contents from contamination and external damage, thereby reducing waste. A few examples of polymer rigid packaging products are clamshells, thermoformed trays, bottles, and containers.

Many suppliers and brands are working to create sustainable rigid plastic packaging. However, it is crucial to make decisions that won’t harm customer safety, satisfaction, or brand loyalty.

If you are looking to test the quality and performance of your rigid packaging materials or new sustainable products, it is important to conduct the tests in an ISO 17025 accredited laboratory like Clear Packaging. This will provide you with accurate data that can help you determine the appropriate specifications and ensure consistency in performance.

Contact Clear Packaging for a testing schematic that will solve your packaging challenges.

We are well-versed in method developments that simulate in-field usage.